Solutions of BMT to increase rutting resistance of asphalt

Along with the development of economy, the demand for road transport is constantly increasing. So that the large number of trucks and trailers is sharply increasing at the moment. As a result, the number of axles and axle load is far greater than initially anticipated. This is the cause for the rapid structural damage to the road surface, which often occurs as rutting on the road, especially at the intersections. In addition, it’s necessary to consider the environmental factors. In particular it is the temperature factor in the tropical regions as our country. Temperature has a direct effect on the rutting process of asphalt pavement. For viscoelastic materials, such as asphalt, the susceptibility to heat is necessary to consider before using.

Rutting is classified into 3 types: rutting on the asphalt surface course, rutting on the base/subbase and rutting happened on both the surface and the base/subbase. The most common type is rutting on the surface course. The BMT researchers have found 3 major mechanism causing rutting:

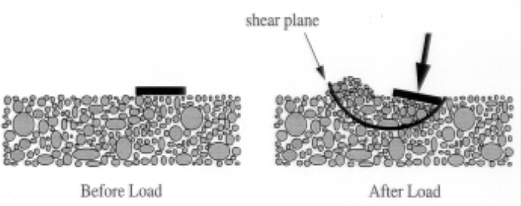

The first mechanism – shear deformation: Rutting due to shear deformation occurs when the load placed on asphalt larger than its load capacity. At that time, asphalt layer will not be stable and sliding surfaces will appear. The asphalt layer just below the wheel tracks will slip into two sides, and the rutting appears on the surface as shown in Figure 1.

Fig. 1 – Rutting due to shear deformation

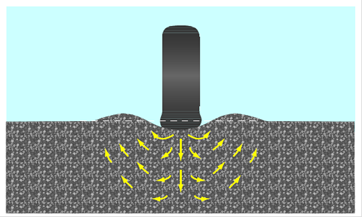

The second mechanism – creep deformation: Rutting due to vertical creep deformation occurs when asphalt temperature rises and duration of load increases. As the temperature increases, the asphalt viscosity decreases. Therefore, it reduces stiffness and hardness of asphalt correspondingly. As the duration increases, the deformation will increase due to accumulating time rise. Creep deformation is not fully recovered when unloading causes rutting.

The third mechanism – post compaction: rutting due to post compaction occurs vertically after the end of compaction in case of lack of compacted density or inappropriate designed air void. When meeting heavy load combined with high temperature the aggregates will be rearranged. This process increases the asphalt density and causes volume reduction. As a result, rutting will appear at wheel track position.

In summary, anti-rutting solution requires a closed coordination of overall factors. Understanding the causes of rutting, alongside quality control from materials testing, design, manufacturing to post- paving, researchers and experts of BMT Research – Development and Testing have been carrying out various research programs to thoroughly eliminate rutting on domestic routes:

1) Modifying bitumen with various additives, thermoplastic chemicals for the purpose of increasing thermal stability, elasticity and cohesion between bitumen and aggregates. In recent times, Dr. Vo Dai Tu and colleagues have developed and successfully produced modified bitumen named BMT-ATR – one of the most effective method to prevent rutting in the conditions in our country.

2) Applying various reinforcing additives, many chemicals forming spatial structure of asphalt, for example cellulose fibers, polyolefin fibers, polyamide fibers, etc.

3) Applying various high-strength aggregate grading as gap grade, open-friction grade for heavy traffic projects, express way, etc.

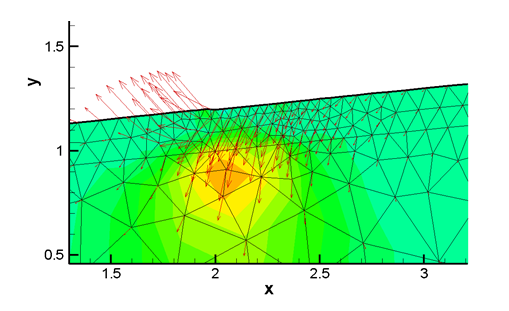

4) Researching mathematic models for rutting prediction. Materials can be correctly chosen and estimated based on appropriate prediction results. Typically, Dr. Nguyen Huynh Tan Tai is developing a rutting prediction model based on theory of Ducker-Prager.

Fig. 2 – Hot mix asphalt specimen using modified bitumen BMT-ATR – one of the most effective anti-rutting method (Head of project – Dr. Vo Dai Tu)

Fig. 3 – Rutting prediction mathematic model of Dr. Nguyen Huynh Tan Tai

Dr. Vo Dai Tu