SARA fraction and Colloidal structure

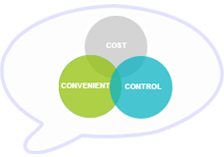

Since manufactured via a crude oil distillation, bitumen is well-known as a complicated composition. Mainly based on different ranges of molecular weight and physo-chemical properties, its components are classified into four groups. They are: Saturates, Aromatic Oils, Resins, and Asphaltenes. The fraction among them, as so-called SARA fraction, helps to calculate Colloidal Index (Ic) that indicates the colloidal structure of bitumen. It, consequently, determines rheology and mechanism of bitumen modification.

Different crude sources provide varied SARA fractions and, therefore, form diverse Colloidal structures. Although two bitumens have similar penetrations and softening points, their huge distinction in other intrinsic consistencies may be observed, such as their Penetration Index (PI) and viscosity at 600C. This fraction also changes during asphalt manufacturing process and the service life of the pavement. Except that saturates basicly retains, aromatic oils content decrease while increasing resins and asphaltenes percentages. This chemical ageing causes the hardening of the material[1].

On the other hand, colloidal structure helps to figure out the compatibility of base bitumen to polymer modification as well. No precious standard was made to identify the borderline between “compatible” and “incompatible” bitumen. However, an obvious relation among SARA fraction, Colloidal Index and rheological performance of various sets of SBS PMBs was examined. In common, the greater aromatic oils amount (lower Ic) leads to a more compatible SBS-bitumen system[2].

Due to the essential importance of SARA fraction, the separation of these four groups has been implemented at BMT Construction & Investment J.S.C. We are looking forward to taking a significant improvement in controlling bitumen quality and bitumen modification.

References:

[1] Didier Lesueur, The colloidal structure of bitumen: Consequences on the rheology and on the mechanism of bitumen modification, Advances in Colloid and Interface Science 145 (2009) 42-82.

[2] Gordon D. Airey, Rheological properties of styrene butadiene styrene polymer modified road bitumens, Fuel 82 (2003) 1709-1719.